Gauss by gloria k.

Therapeutic Jewellery

Clanny Lamp Timeline

1813: William Reid Clanny [Irish doctor] presents a research paper to the Royal Society of Arts for a closed-flame oil lamp to replace the candle and the naked-flame lamp.

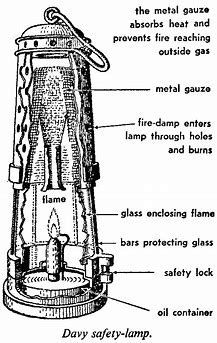

1816: Sir Humphry Davy [Cornish chemist] invents the closed-flame safety lamp that detects *methane

&

*firedamp.

The safety lamp works, but only if it is in “perfect working order”. Any tiny damage to the mesh flame-cover or a loose brass seal securing the glass within the chamber results in

Explosion & *Afterdamp.

1893: Nova Scotia government gives exclusive mining and mineral rights lease to an American Syndicate, The Dominion Coal Company. [99 year lease]

For over a century, Cape Breton coal miners descend into deeper, bigger, more dangerous coal mines using the Clanny Lamp - before modern day gas detectors.

Closed-flame Clanny [safety lamps] were often a “lure to danger” for the coal miners by The Dominion Coal Company.

1930: Tungsten filaments replace carbon flame-lighting helmets. Electric [alkaline battery operated] lamps were hand held, but later mounted on the miner’s helmets. Referred to as a "white light". The alkaline batteries were mounted on the miner’s back with a cord running to his helmet. (pictured in my Coal Black Magnetic Jewellery gallery)

Overmen and shotfirers continued to carry the Davy safety lamp to detect methane gas, firedamp or coal dust until modern day electronic gas detectors.

1998.The lithium battery, electric L.E.D helmet light, now used in modern mines improve the miners’ lighting but not his safety. White light miners’ helmets must be combined with sophisticated [perfectly operating] modern gas detectors for the miners to work in safe conditions as defined by The Nova Scotia Labor Department (1989).

2023. Many mines throughout the World are still using naked-flame lamps or Clanny lamps to detect methane gas and firedamp!

These miners can only pray the *Lamp Cabin personnel (on the surface, in front of the *Pit Head) are handing out perfectly maintained safety lamps.

Afterdamp

is a choking gas, rich in carbon monoxide, left after an explosion of firedamp in a coal mine.

Firedamp is a flammable, combustible gas combination found in coal mines [mostly methane]. Dangerously explosive when mixed with air or any type of flame.

Lamp Cabin is the place where the lamps are stored, repaired and filled with kerosene lamp oil. Miners picked up their lamps, walked through the lamp cabin to the end door, which lead directly to the pit head and underground.

Methane gas [carbon and hydrogen] is released as a direct result of physical coal extraction. The coal releases methane previously trapped within the seam into the air supply. This creates a potential safety hazard if air vents and gas detectors are not fully operational. Bituminous coal [mined in Cape Breton] has the highest ratio of methane gas in the coal seam. Methane emissions are also caused by the collapse of surrounding rock after the coal seam has been mined, and when the artificial roof [steel arch rails] and wall supports [dummy walls] are removed as mining progresses to another section. "Collapsing the Gob"

Overmen [foreman or overseer] is directly involved with the workings of the pit. If a colliery [mine] has a number of pits, there is an overman to each pit.

Pit Head is the top of a mining pit or coal shaft.

Shotfirers assemble, position and detonate explosives at the mining site to dislodge rock or soil.

Cape Breton Coal Miners

www.capebretonbooks.com/products/that-bloody-cape-breton-coal

Virtual Tour

Goggle Shopping Trusted Store

"High Quality Customer Experience"

Goggle Shopping Trusted Store

High Quality Customer Experience

Gauss by gloria k.

Therapeutic Jewellery

Design - Images - Content

All Rights Reserved